Big Box

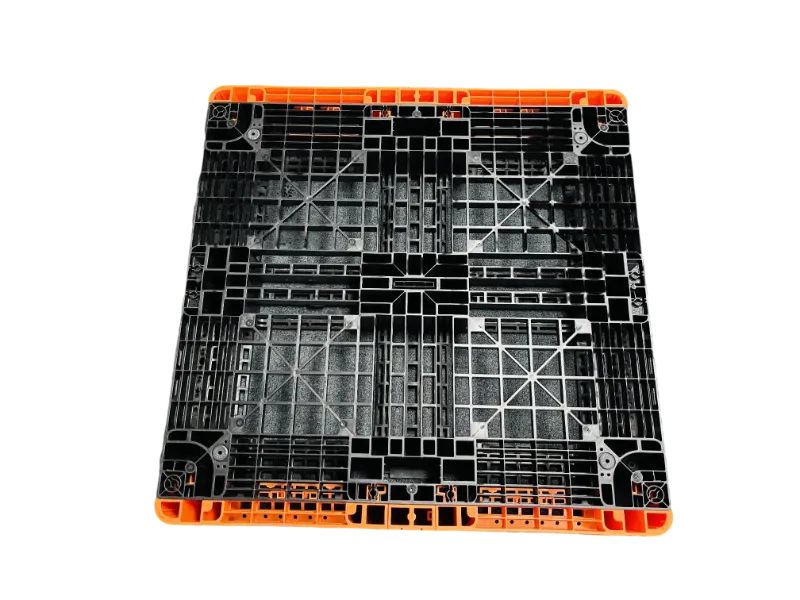

Oversized molding

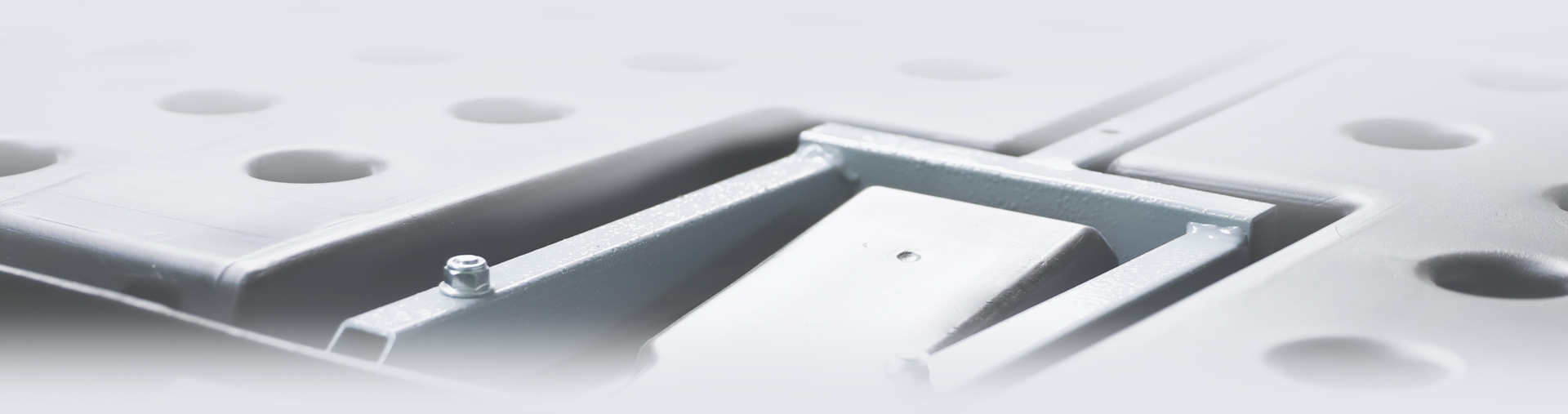

Frame-type built-in steel pipe

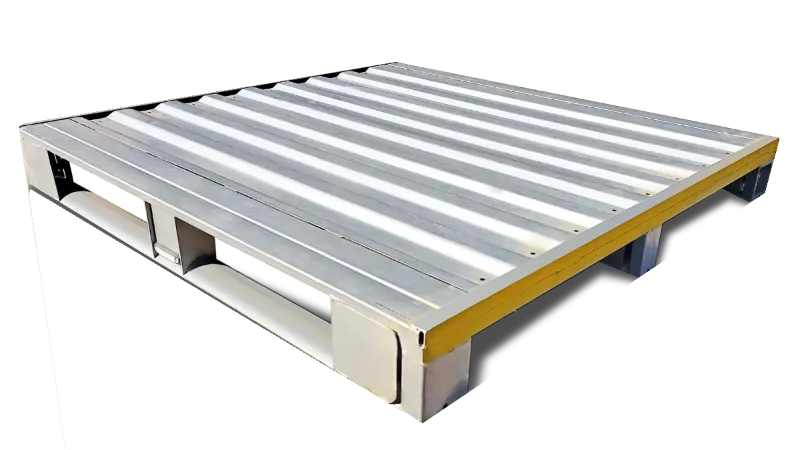

Forklift interface size design

Tightening belt

BIGBox is a high-capacity, ultra-durable logistics container designed for oversized and heavy components. Its reinforced structure, large internal volume, and standardized footprint make it ideal for industries like EV batteries, automotive parts, and large modular assemblies.

Built using advanced double-layer molding technology with steel-frame reinforcement, BIGBox delivers exceptional load-bearing strength while maintaining stability and safety in transport. Optimized for forklift handling, stacking, and efficient container utilization, it boosts operational flow and reduces overall logistics cost.

As part of the ALSCO Group’s sustainable pooling ecosystem, BIGBox supports reusable packaging, cuts waste, and enhances supply-chain efficiency for large-format goods.

Product Specifications

| Length (L) | Width (W) | Height (H) |

|---|---|---|

| 2270 mm | 1485 mm | Customizable |

| 2270 mm | 1690 mm | Customizable |

Adaptability

The size chain fully adapts to the container size design.

The BIGBox series is engineered around a size chain that matches container dimensions with precision. The lineup includes three models — B17, B15, and B13 — all built with a fixed width of 2270 mm, while the lengths vary to optimize different loading configurations: 1690 mm (fits 7 units in a 40-foot container), 1320 mm (fits 8 units), and 1185 mm (fits 9 units). This container-driven design ensures maximum space utilization inside shipping containers, helping industries cut internal logistics waste and boost efficiency.

advanced technology

Ultra-large molding, the first in the industry

The base is equipped with the world-class GEISS T10 double-layer blister machine, enabling high-efficiency, high-quality production of oversized hoardings.

With integrated molding technology, the structure achieves high strength, making it suitable for heavy-load carrying, transportation, and stacking applications.

Advanced structure

Stronger carrying capacity

Because batteries, motors, and other components add significant weight, preventing deformation of the bottom cover and maintaining enclosure-joint sealing becomes critical.

The BIGBox series addresses this with a built-in steel pipe structure and a frame-type steel pipe layout in the bottom cover, ensuring uniform force distribution and greatly enhanced load-bearing capacity.

For the hoardings, C-shaped, L-shaped, and aluminum-alloy configurations are used, providing stable structural support while preserving a refined, aesthetic appearance.

Packaging Optimization

Product Gallery

Ready to transform your supply chain?

Reach out to our team to discover how ULS Pooling can boost efficiency and sustainability across your operations.