Jet Box

Lighter and low-drag design

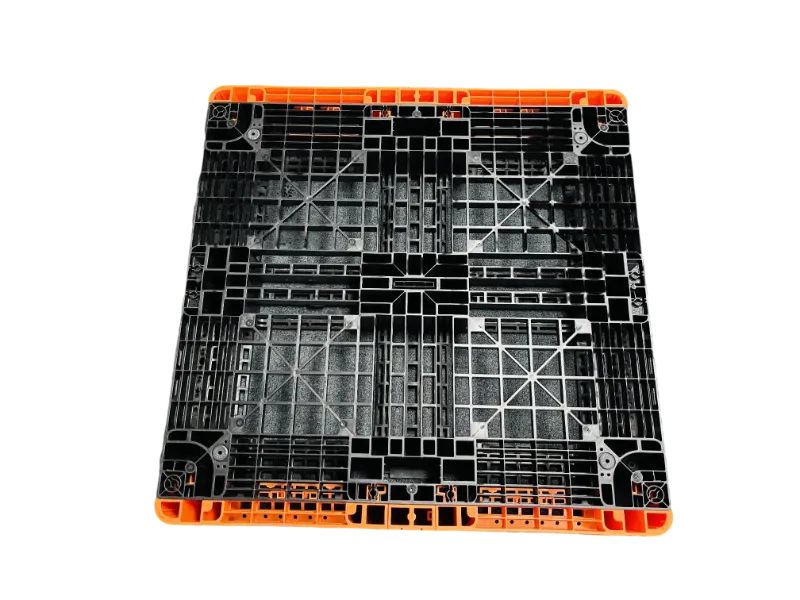

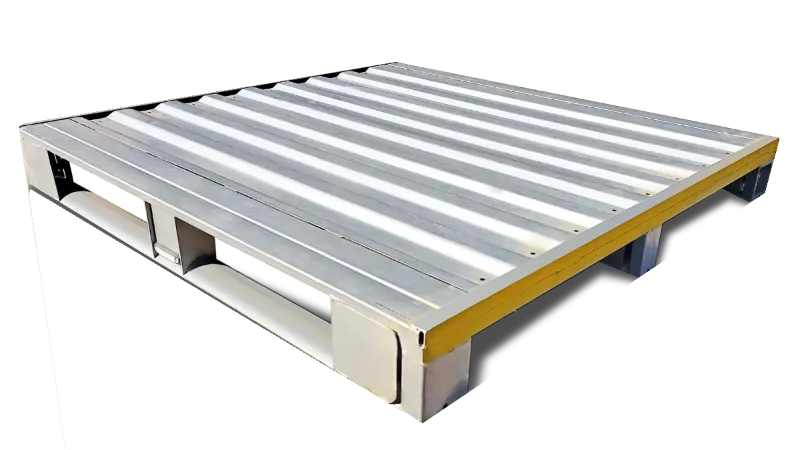

Composed with aluminum and PP honeycomb -“cradle to cradle”

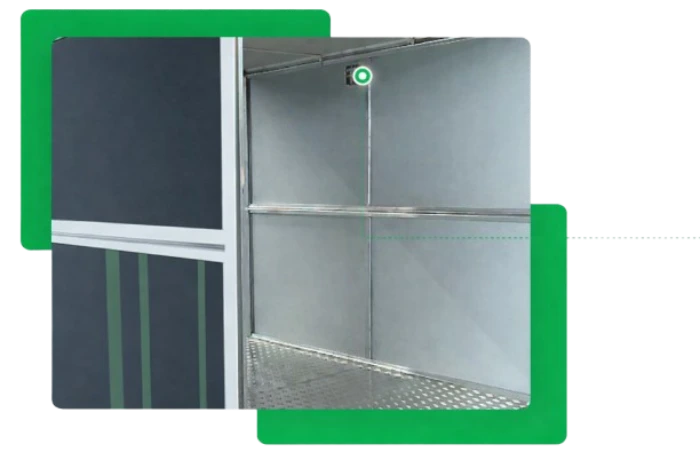

Equipped with Blue-box: Remote, real-time monitor-location, temperature, etc.

Scan cargo without unpacking and openning by RFID enable

The Jet Box is designed to provide secure, organized, and space-efficient storage for medium-sized goods. Built with durable materials and a strong base structure, it ensures safe handling throughout transportation and warehouse operations. Its optimized shape and standardized dimensions allow easy stacking, better space utilization, and faster workflow.

With generous internal volume and customizable height options, the Jet Box adapts easily to different product requirements, whether for automotive parts, retail goods, manufacturing components, or export shipments. The container’s reinforced walls, sturdy base, and reusable design help companies reduce packaging waste, cut operational costs, and minimize product damage.

Crafted from long-lasting, reusable material, the Jet Box minimizes packaging waste while delivering consistent performance in every cycle. With clear labeling areas and a stable structure, it enhances inventory tracking, product protection, and overall efficiency. Whether used in manufacturing, automotive, retail, or distribution centers, the Jet Box supports a cleaner, smarter, and more sustainable way of managing goods. ,

Product Specifications

| Model no. | Outer Size L × W × H (mm) |

Inner Size L × W × H (mm) |

Door Frame Size (mm) | Inside Volume (m³) | Weight (kg) | Maximum Loading (kg) |

|---|---|---|---|---|---|---|

| M1 (8 feet) | 2550 × 2170 × 1400 | 2500 × 2130 × 1235 | 2040 × 1185 | 6.3 | 290 | 1000 |

| M2 (8 feet) | 2550 × 2170 × 2800 | 2410 × 2130 × 2635 | 2040 × 2585 | 13.5 | 480 | 3000 |

| L1 (10 feet) | 2550 × 3000 × 1400 | 2465 × 2930 × 1230 | 2420 × 1150 | 8.3 | 550 | 2500 |

| L2 (10 feet) | 2550 × 3000 × 2800 | 2465 × 2930 × 2630 | 2420 × 2550 | 18.9 | 800 | 6000 |

Energy-saving and emission-reducing design

Making logistics green

The box body uses an aluminum-alloy frame combined with PP honeycomb panels, both of which are recyclable materials.

Its lightweight structure and low wind-resistance design help improve energy savings and reduce emissions.

Reduce loading and unloading time

Fast loading and unloading, fast delivery

The operation workflow is as follows:

goods packing → door sealing and box locking → forklift loading → locking and securing → long-distance transportation → forklift unloading.

Using a forklift for both loading and unloading significantly improves vehicle handling efficiency and reduces overall waiting time.

Real-time tracking

No matter how far away you are, you can control it in real time

An intelligent IoT module can be installed inside the compartment to enable remote, real-time monitoring of cargo information such as geographical location, temperature, and other key parameters.

Product Gallery

Ready to transform your supply chain?

Reach out to our team to discover how ULS Pooling can boost efficiency and sustainability across your operations.